PriceInquire

PriceInquire

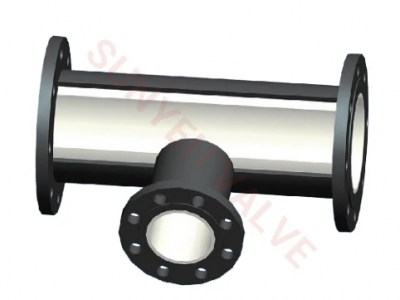

Abrasion Resistant Ceramic Lined Pipe

Sunyeh

The abrasion-resistant ceramic pipeline, composed of alumina ceramic lined pipes (or zirconia) and seamless ceramic lined steel pipes with a special adhesive, forms a solid anti-wear layer. abrasion resistant ceramic lined pipe offers abrasion, corrosion, and heat resistance, ideal for conveying abrasive and corrosive materials in various industries.

Our company Sun Yeh,one of the leading ceramic lined pipe manufacturers, can provide abrasion-resistant ceramic lined pipe such as ceramic lined carbon steel pipe, stainless steel, and ductile iron according to the specific operating conditions and requirements of the customers.

Application of Abrasion Resistant Ceramic Lined Pipes

Abrasion resistant ceramic lined pipes are widely used in the following fields:

Coal thermal power plants: used to transport materials such as coal ash slurry to reduce pipe wear and corrosion.

Mining industry: in the mine transportation system, the abrasion resistant ceramic lined pipes are used for conveying abrasive materials such as ores and tailings to improve transportation efficiency and safety.

Chemical industry: used for conveying various acids, alkalis, salts, and other corrosive chemicals.

Oil and gas industry: used for conveying crude oil, natural gas, and other media, especially in mixtures containing solid particles.

Characteristics of Abrasion Resistant Ceramic Lined Pipe

The wear-resistant ceramic pipeline is composed of alumina ceramic lined pipe (or zirconia) and seamless ceramic lined steel pipe. Special corundum ceramics are combined with seamless steel pipe by special adhesive. After 24 hours of curing, a solid anti-wear layer is formed. In unique structural design each piece of ceramic is grinded to a suitable angle, so that each circle of ceramics blocks form a 360° mechanical self-locking force, to ensure that ceramics and ceramics, ceramics and steel pipe bonding closely. The adhesives have excellent bonding properties to steel in the ceramic lined steel pipes and ceramics in the ceramic lined pipes, high strength and toughness, high heat resistance and aging resistance, and can be operated for a long time at 50°C to 500°C.

The abrasion resistant ceramic lined pipe has the properties of abrasion resistance, corrosion resistance and heat resistance. Abrasion resistant ceramic lined pipe is an ideal product for conveying materials with high grinding and corrosion medium such as sand, stone, coal powder, ash and liquid aluminum. Wear-resistant ceramic lubes have high wear resistance and fluid erosion resistance. in practice. wear-resistant ceramic tubes were opened for observation and measurement after one year of usage, and there was no obvious wear or shedding.

Anti-abrasive,anti-abrasive valves pipe and fitting in corrosive or high-temperature places are suitable for: ash removal, slag discharge powder feeding and powder returning systems in coal-fired power plants; ceramic lined pipes for blast furnace coal injection and slag conveying steelworks; pipes for iron alloy conveying and refining outside the furnace; raw slurry conveying, pulverized coal conveying, discharging of hoists, and concrete conveying pipeline in cement plants.

Advantages of Abrasion Resistant Ceramic Lined Pipes

Abrasion resistant ceramic lined pipes have the following significant advantages:

Excellent abrasion resistance:

ceramic lining can effectively protect the underlying steel pipe from abrasion and prolong the service life of the abrasion resistant ceramic lined pipe, especially suitable for conveying abrasive or corrosive media.

Corrosion resistance:

ceramic materials of the abrasion resistant ceramic lined pipe usually have good chemical stability, can resist the erosion of a variety of chemical substances, suitable for use in chemical and other industries.

High temperature resistance:

ceramic materials can withstand high operating temperatures and are suitable for conveying materials in high temperature environments.

Reduced maintenance costs:

due to the abrasion resistant ceramic lined pipe's excellent wear and corrosion resistance, abrasion resistant ceramic lined pipes can reduce the number of maintenance and repair costs.

Specification of Abrasion Resistant Ceramic Lined Pipe

Body Size

DN | R | Steel pipe size | Ceramic size | ΦD | ΦK | ΦG | N-D | T | f |

15 | 1.5D/2D/2.5D | Φ32x3 | Φ25x5 | 95 | 65 | 45 | 4-Φ14 | 14 | 2 |

20 | 1.5D/2D/2.5D | Φ38x4 | Φ30x5 | 105 | 75 | 55 | 4-Φ14 | 16 | 2 |

25 | 1.5D/2D/2.5D | Φ45x5 | Φ35x5 | 115 | 85 | 65 | 4-Φ14 | 16 | 2 |

32 | 1.5D/2D/2.5D/3D | Φ50x4 | Φ42x5 | 140 | 100 | 76 | 4-Φ18 | 18 | 2 |

40 | 1.5D/2D/2.5D/3D | Φ60x5 | Φ50x5 | 150 | 110 | 84 | 4-Φ18 | 18 | 3 |

50 | 1.5D/2D/2.5D/3D | Φ73x6 | Φ61x6 | 165 | 125 | 99 | 4-Φ18 | 20 | 3 |

65 | 1.5D/2D/2.5D/3D | Φ89x5 | Φ79x7 | 185 | 145 | 118 | 4-Φ18 | 20 | 3 |

80 | 1.5D/2D/2.5D/3D/3.5D | Φ108x5 | Φ98x9 | 200 | 160 | 132 | 8-Φ18 | 20 | 3 |

100 | 1.5D/2D/2.5D/3D/3.5D | Φ133x6 | Φ121x10 | 220 | 180 | 156 | 8-Φ18 | 22 | 3 |

125 | 1.5D/2D/2.5D/3D/3.5D/4D | Φ159x7 | Φ145x10 | 250 | 210 | 184 | 8-Φ18 | 22 | 3 |

150 | 1.5D/2D/2.5D/3D/3.5D/4D | Φ180x5 | Φ170x10 | 285 | 240 | 211 | 8-Φ23 | 24 | 3 |

200 | 1.5D/2D/2.5D/3D/3.5D/4D-10D | Φ245x8 | Φ229x13 | 340 | 295 | 266 | 12-Φ23 | 24 | 3 |

250 | 1.5D/2D/2.5D/3D/3.5D/4D-10D | Φ299x10 | Φ279x13 | 405 | 355 | 319 | 12-Φ26 | 30 | 3 |

300 | 1.5D/2D/2.5D/3D/3.5D/4D-10D | Φ340x8 | Φ324x13 | 460 | 410 | 370 | 12-Φ26 | 30 | 3 |

Notes: Pipeline diameter is less than 12 inches, internal ceramics are assembled by integral ceramic pipe technology; diameter is more than 12 inches, assembled by ceramic tile masonry technology.

For top-quality ceramic valves that excel in durability and precision, trust Sun Yeh. Contact us today to discuss your requirements and place your order.

Abrasion Resistant Ceramic Lined Pipe FAQs

What factors should I consider when choosing abrasion resistant ceramic lined pipes?

When choosing abrasion resistant ceramic lined pipes, you should consider the following key factors:

1. abrasion resistant ceramic lined pipe performance: the main function of abrasion resistant ceramic lined pipes is to resist wear and tear, so abrasion resistant ceramic lined pipes' abrasion-resistant performance should be prioritized when choosing. The hardness and wear resistance of the ceramic material are the key factors determining abrasion resistant ceramic lined pipes' performance.

2. Chemical stability: the abrasion resistant ceramic lined pipe may come into contact with corrosive media in the course of use, so it is necessary to choose materials with good chemical stability to avoid erosion of the abrasion resistant ceramic lined pipe leading to a shortened life.

3. Temperature adaptability: temperature changes in different working conditions may have an impact on the pipeline material, the choice of a good temperature adaptability of the material can ensure that the pipeline is in the high-temperature or low-temperature environment of normal operation.

4. Cost considerations: different materials abrasion resistant ceramic lined pipe cost differences, need to be based on the actual budget for comprehensive consideration.

5. Use environment: According to the specific working environment where the abrasion resistant ceramic lined pipe is located, such as the type of transported materials, particle size, the use of temperature and the flow rate of the material, etc., to choose the appropriate abrasion resistant ceramic lined pipe specifications and models.

6. Installation and maintenance: Considering the installation convenience and maintenance cost of the pipeline, choose the pipeline design that is easy to install and maintain.

7. Manufacturer's reputation: Choose well-known brands and manufacturers with good reputations to ensure the quality of piping and after-sales service.

8. Product standards: Ensure that the selected piping complies with relevant industry standards and codes to ensure abrasion resistant ceramic lined pipes' performance and safety.

By combining these factors, you can choose the abrasion resistant ceramic lined pipe that best suits your specific application needs.

Is abrasion resistant ceramic lined pipe more resistant to scratches than steel?

Abrasion resistant ceramic lined pipes typically exhibit higher hardness and wear resistance compared to steel, making them more effective at resisting scratches. Ceramic materials can achieve a Mohs hardness level of 9, significantly higher than most steels. Consequently, when handling hard particles or abrasive substances, abrasion resistant ceramic lined pipes provide superior protection and reduce the risk of scratches and abrasion. However, it's important to note that even abrasion resistant ceramic lined pipes can sustain damage from impacts involving sharp objects or intense pressure. Therefore, it is crucial to consider specific application scenarios and potential risks when selecting piping materials.

What are abrasion resistant ceramic lined pipes?

Abrasion resistant ceramic lined pipes are a special type of industrial pipe whose inner wall is covered by a layer of hard ceramic material. This layer of ceramic material, often made of aluminum oxide, is extremely hard and abrasion-resistant, effectively resisting abrasion and scratching. The outer layer of abrasion resistant ceramic lined pipes is often made of carbon steel, and the middle layer is an adhesive that holds the ceramic layer firmly in place on the steel pipe. This structure makes the abrasion resistant ceramic lined pipes show excellent performance in conveying abrasive materials, corrosive media, and other harsh working conditions.

What is the lifespan of abrasion resistant ceramic lined pipes?

The service life of abrasion resistant ceramic lined pipes is affected by a variety of factors, including the type of material to be conveyed, the size of the particles, the use of temperature and the flow rate of the material. Generally speaking, if the pipeline conveys powder powder material, the powder on the inner wall of the abrasion resistant ceramic lined pipes wear is small, the service life of the abrasion resistant ceramic lined pipe can be up to one or two years or even longer. If the granular material conveyed is large, such as stone size, the impact friction on the inside of the abrasion resistant ceramic lined pipe is larger, the ceramic inside the abrasion resistant ceramic lined pipe is easy to smash and fall off, and the abrasion resistant ceramic lined pipe is more likely to be damaged. In addition, if the abrasion resistant ceramic lined pipe is used in a high temperature environment, for example, above 300 degrees, the ceramics are prone to fall off, and the life of the abrasion resistant ceramic lined pipe will be shortened.

Under ideal working conditions, the life of abrasion resistant ceramic lined pipes is 8-10 times higher than cast stone pipes, wear-resistant alloy steel pipes, and 15-20 times higher than steel-plastic and steel-elastomer bends. In order to ensure the best performance and longest service life of the abrasion resistant ceramic lined pipe, the abrasion resistant ceramic lined pipes should be designed and selected according to the specific conditions of use of the appropriate pipe.

view details

view detailsCN ¥12644.00

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsCN ¥245.00

view details

view detailsInquire

本网页所展示的有关【Abrasion Resistant Ceramic Lined Pipe】的信息/图片/参数等由的会员【Sunyeh Control Valve Group Co., Ltd】提供,由peakexporter.com会员【Sunyeh Control Valve Group Co., Ltd 】自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。您在本网页可以浏览【Abrasion Resistant Ceramic Lined Pipe】有关的信息/图片/价格等及提供【Abrasion Resistant Ceramic Lined Pipe】的商家公司简介、联系方式等信息。

在您的合法权益受到侵害时,请您致电,我们将竭诚为您服务,感谢您对peakexporter.com的关注与支持!