PriceInquire

PriceInquire

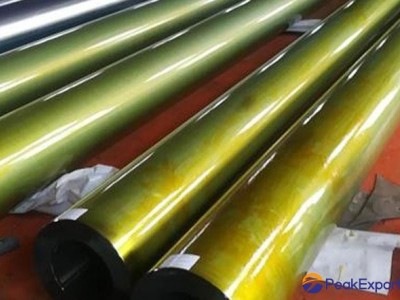

Alloy steel seamless pipes are indispensable in a variety of industrial settings, particularly those that demand high-temperature resilience. Renowned for their robustness, substantial strength, and capability to endure extreme conditions, these pipes are integral to industries such as power generation, chemical processing, and oil and gas. This product introduction will guide you through the critical specifications, dimensions, manufacturing processes, and applications of alloy steel seamless pipes, illustrating their significance in modern industrial practices.

Specifications and Standards

The remarkable performance of alloy steel seamless pipes is underpinned by adherence to stringent international standards. These standards ensure the pipes offer unparalleled quality, reliability, and safety in demanding environments.

ASTM A335: This specification encompasses seamless ferritic alloy-steel pipes designed for high-temperature service. Popular grades such as P1, P11, P12, P22, P5, P9, and P91 are widely used. These pipes excel in applications involving bending, flanging, and fusion welding due to their enhanced ductility and toughness.

JIS Standards (G3458, G3462, G3467): Originating from Japan, these standards cover alloy steel pipes appropriate for high-temperature service, along with boiler and heat exchange tubes. The STPA and STbaseries meet rigorous demands of high-pressure and high-temperature applications in various energy systems.

DIN 17175-79: This German standard applies to welded steel tubes optimized for high-temperature settings, often employed in environments necessitating sustained thermal endurance.

Dimensions

Alloy steel seamless pipes are available in a diverse range of dimensions to meet specific industrial needs:

Outside Diameter: Ranges from 20 mm to 1066.8 mm, accommodating various flow requirements.Wall Thickness: Varies from 1 mm to 80 mm, allowing customized solutions to handle distinct pressure and thermal loads.A335 and A333 Pipe Specifications

A335 Pipes: Available in sizes from NPS 1/4" to 24", these pipes cater to severe high-temperature conditions. Their schedules, ranging from 40 to 160 and including STD, XH, and XXH, provide options for varying wall thicknesses, ensuring their adaptability and strength.

A333 Pipes: Engineered for low-temperature environments, they are available in sizes NPS 1/4" to 24". This specification includes ferritic steel grades designed to mitigate low-temperature impacts, enhancing safety and efficiency across applications.

Manufacturing and Heat Treatment

The production of alloy steel seamless pipes employs advanced methods like hot finishing or cold drawing to achieve the required specifications. ASTM A333 pipes particularly undergo meticulous heat treatment to optimize their structure and performance:

Normalizing: Adjusts the microstructure to enhance toughness.Quenching and Tempering: Boosts strength and ductility, essential for high-pressure conditions.Double Normalized and Tempered: Offers a uniform microstructure and enhanced performance, tailored for the most demanding applications.Boiler and Mechanical Tubing

In boiler and mechanical applications, alloy steel seamless pipes are critical for constructing components like waterwalls, economizers, and superheaters:

SA213 / A213: Encompasses grades such as T-5, T-9, T-11, T-22, and T-91, offering excellent high-pressure and high-temperature properties, essential for power generation and petrochemical applications.

SA210 / A210: Primarily utilized in lower pressure setups, yet they maintain robust performance, particularly in Grade A1 format.

For broader mechanical uses, ASTM A519 is frequently employed in grades 1026, 4130, and 4140. These cater to systems transporting fluids such as steam, water, and gas under significant pressure and temperature, ensuring operational integrity and safety.

Conclusion

Alloy steel seamless pipes are pivotal in ensuring efficiency and safety in high-temperature and high-pressure industrial applications. Their rigorous compliance with international standards, a wide array of dimensions, and sophisticated manufacturing processes enable them to meet the stringent requirements of modern industries. By selecting the appropriate specifications and materials, industries can optimize performance and longevity in their piping systems, leading to improved operational outcomes and safety.

view details

view detailsInquire

view details

view detailsCN ¥195.00

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsCN ¥195.00

view details

view detailsCN ¥20.00

本网页所展示的有关【Alloy seamless steel tube】的信息/图片/参数等由的会员【SHANGHAI JUYE MATERIAL TECHNOLOGY CO.,LTD】提供,由peakexporter.com会员【SHANGHAI JUYE MATERIAL TECHNOLOGY CO.,LTD 】自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。您在本网页可以浏览【Alloy seamless steel tube】有关的信息/图片/价格等及提供【Alloy seamless steel tube】的商家公司简介、联系方式等信息。

在您的合法权益受到侵害时,请您致电,我们将竭诚为您服务,感谢您对peakexporter.com的关注与支持!