PriceInquire

An aluminum degasser is a vital tool in aluminum processing. It removes hydrogen and other impurities from molten aluminum. By bubbling an inert gas through the melt, it improves the quality of the aluminum, reducing porosity in castings and enhancing mechanical properties.

TYPES OF ALUMINUM DEGASSER

Degassing in Aluminium Casting Machine

Aluminum Chip Dryer

ENHANCING metaL PURITY WITH AN ADVANCED ALUMINUM DEGASSER

01

Hydrogen Removal

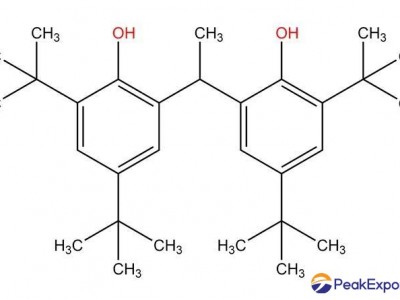

Hydrogen is a common and troublesome impurity in molten aluminum. An advanced aluminum degasser effectively extracts hydrogen from the melt. By introducing an inert gas, like argon, which forms tiny bubbles, hydrogen diffuses into these bubbles and is carried out of the molten metal. This reduces porosity in the final aluminum products, making them stronger and more reliable.

02

Removal of Other Impurities

Besides hydrogen, the degasser can also help eliminate non - metallic inclusions such as oxides. As the inert gas bubbles rise through the molten aluminum, they act like tiny scavengers, attaching to these impurities and bringing them to the surface. This results in a cleaner, purer aluminum melt, which is crucial for high - quality casting applications.

03

Improved Mechanical Properties

With enhanced purity achieved by the degasser, the mechanical properties of aluminum are significantly enhanced. Products made from degas aluminum have better tensile strength, ductility, and fatigue resistance. This makes them suitable for demanding industries like aerospace and automotive, where the integrity of aluminum components is of utmost importance.

WHY ALUMINUM DEGASSER IS CRUCIAL FOR HIGH-QUALITY CASTING

An ultrasonic degassing of molten aluminum machine is crucial for high-quality casting. During the melting process, aluminum absorbs hydrogen and other impurities. These can cause porosity and defects in castings. A degasser removes hydrogen by bubbling an inert gas through the molten metal. It also eliminates non - metallic inclusions. This results in castings with better mechanical properties, ensuring they meet the high standards of various industries.

FAQS OF ALUMINUM DEGASSER

How does an aluminum degasser work?

A nitrogen degassing aluminum machine operates based on the principle of gas flotation. It introduces an inert gas, typically argon or nitrogen, into the molten aluminum. As the gas bubbles rise through the melt, hydrogen and other impurities, such as oxides, diffuse into these bubbles. The bubbles then carry the impurities to the surface of the molten aluminum, where they can be skimmed off, thus purifying the melt.

What are the benefits of using an aluminum degasser?

Using an aluminum degasser significantly improves the quality of aluminum castings. By removing hydrogen, it reduces porosity, which in turn enhances the mechanical properties of the final product. This leads to stronger, more durable aluminum components with better fatigue resistance and tensile strength. It also helps in achieving a more uniform microstructure, crucial for applications in industries like aerospace and automotive.

How often should an aluminum degasser be maintained?

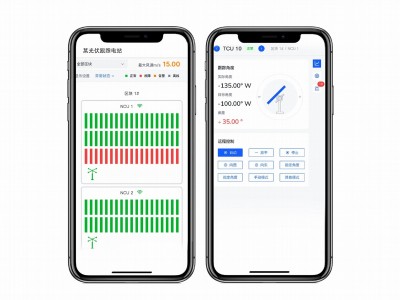

Maintenance frequency depends on usage. For continuous, high - volume operations, regular daily checks are recommended. This includes inspecting the gas supply lines for leaks, checking the condition of the degassing rotor (if applicable), and ensuring proper functioning of control systems. Periodically, usually every few months, more in - depth maintenance such as cleaning internal components and calibrating sensors may be required to keep the degasser operating at peak efficiency.

Can an aluminum degasser be used for other metals?

While primarily designed for aluminum, some degassers can be adapted for certain other non-ferrous metals with similar melting characteristics, like magnesium alloys. However, the specific design and gas used may need to be adjusted. For example, the degassing temperature and the type of inert gas might vary depending on the metal's properties. But for metals with very different chemistries, such as steel, a different type of degassing equipment is typically required.

How do I choose the right aluminum degasser for my operation?

Consider the volume of aluminum you process. For small-scale foundries or hobbyists, a compact, manual or semi-automatic degasser may suffice. Larger industrial operations need high-capacity, fully-automated degassers. Also, look at the level of purity required. If you're producing high-end components for critical applications, you'll need a more advanced degasser with precise control over the degassing process. Cost, maintenance requirements, and compatibility with your existing melting equipment are other important factors to consider.

If you want to know more types of recycling plant and machinery, please visit our website.

view details

view detailsCN ¥9000.00

view details

view detailsCN ¥11000.00

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsCN ¥1.00

view details

view detailsCN ¥5.00

view details

view detailsInquire

本网页所展示的有关【Aluminum Degasser for Sale】的信息/图片/参数等由的会员【Hebei Yuebang environmental protection Technology Co., LTD】提供,由peakexporter.com会员【Hebei Yuebang environmental protection Technology Co., LTD 】自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。您在本网页可以浏览【Aluminum Degasser for Sale】有关的信息/图片/价格等及提供【Aluminum Degasser for Sale】的商家公司简介、联系方式等信息。

在您的合法权益受到侵害时,请您致电,我们将竭诚为您服务,感谢您对peakexporter.com的关注与支持!