PriceCN ¥150.00

PriceCN ¥150.00

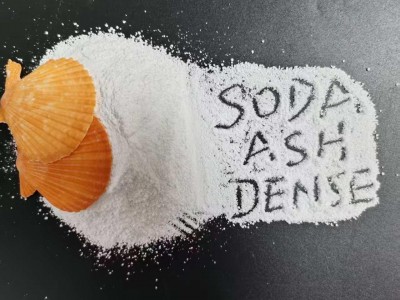

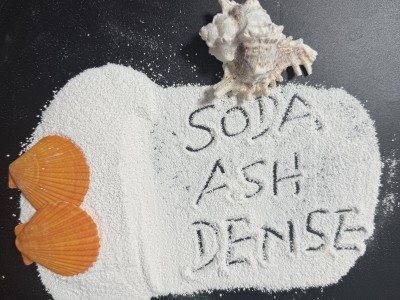

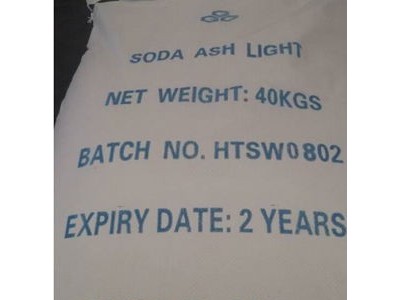

Soda ash, chemically known as sodium carbonate (Na₂CO₃), is a crucial raw material in the glass - making industry.

Composition and Chemical Properties

Soda ash is an inorganic compound. It exists as a white, odorless powder or crystalline solid. It is highly soluble in water, and its aqueous solution is alkaline due to hydrolysis. The chemical formula Na₂CO₃ indicates that each molecule consists of two sodium (Na⁺) ions, one carbonate (CO₃²⁻) ion. This chemical structure gives soda ash its characteristic properties that are beneficial in glass production.

Role in Glass - making

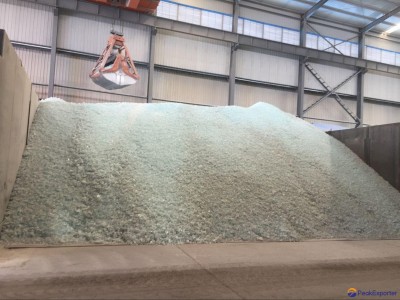

Fluxing Agent In glass manufacturing, soda ash acts as a flux. Glass - making typically involves melting a mixture of silica (SiO₂), which has a very high melting point (around 1713 °C). By adding soda ash, the melting temperature of the silica - based mixture is significantly reduced. Soda ash reacts with silica during the melting process. The carbonate ions in soda ash decompose, releasing carbon dioxide (CO₂) gas. The sodium ions then interact with the silica network, breaking down the strong Si - O bonds in silica and lowering the viscosity of the molten glass. This allows the glass - making materials to be melted at a more manageable temperature, usually around 1500 - 1600 °C, saving energy and reducing production costs.Improving Workability The addition of soda ash also improves the workability of the molten glass. As it reduces the viscosity, the molten glass becomes more fluid, which makes it easier to shape into various forms such as sheets, bottles, or other glass products. Workers can manipulate the glass more easily during the forming process, whether it is through blowing, pressing, or rolling techniques.Enhancing Transparency Soda ash helps in achieving better transparency in the final glass product. By promoting the even melting and mixing of the glass - making ingredients, it reduces the presence of impurities and inhomogeneities that could scatter light and reduce the clarity of the glass. A more homogeneous glass structure, facilitated by soda ash, results in a product with high optical quality, which is especially important for applications such as window glass, optical lenses, and glass containers where transparency is a key requirement.Quality Requirements in Glass - making

High - quality soda ash is essential for producing high - grade glass. The purity of soda ash is crucial. Impurities in soda ash, such as iron oxide, can discolor the glass, leading to an undesirable tint. For example, even a small amount of iron can give the glass a greenish or brownish hue, which is unacceptable for clear glass products. Therefore, soda ash used in the glass industry typically has a high level of purity, often with strict limits on the amount of impurities allowed. Additionally, the particle size distribution of soda ash can also affect the melting process. Uniform particle sizes ensure consistent and efficient melting, contributing to the quality and reproducibility of the glass - making process.

view details

view detailsInquire

view details

view detailsCN ¥695.00

view details

view detailsCN ¥300.00

view details

view detailsCN ¥230.00

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsCN ¥1.00

view details

view detailsCN ¥220.00

view details

view detailsInquire

本网页所展示的有关【Soda Ash Industrial Uses Applications】的信息/图片/参数等由的会员【SHANDONG OCEAN CHEMICAL CO.,LTD】提供,由peakexporter.com会员【SHANDONG OCEAN CHEMICAL CO.,LTD 】自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。您在本网页可以浏览【Soda Ash Industrial Uses Applications】有关的信息/图片/价格等及提供【Soda Ash Industrial Uses Applications】的商家公司简介、联系方式等信息。

在您的合法权益受到侵害时,请您致电,我们将竭诚为您服务,感谢您对peakexporter.com的关注与支持!