PriceCN ¥0.08

PriceCN ¥0.08

Product Overview

MFGsourcing specializes in high-performance custom double-sided EVA foam tape designed to meet the rigorous demands of electronics manufacturing across EVT (Engineering Validation Test), DVT (Design Validation Test), and PVT (Production Validation Test) phases. Our tape combines superior shock absorption, sealing, and vibration damping properties with exceptional durability, making it ideal for protecting sensitive components during development and mass production. Crafted from eco-friendly EVA foam coated with high-tack acrylic adhesive, it ensures reliable bonding even under temperature fluctuations (-40°C to 150°C 9) and harsh environmental conditions.

⚙️ Detailed Die-Cutting Manufacturing Process

Material Selection :

We use A-grade eco-friendly EVA foam (hardness 25-70°, thickness 0.5mm–100mm customizable) , paired with rubber or acrylic adhesives for optimal bond strength.

Precision Slitting and Cutting :

EVA foam is slit into strips using laser-guided tools to minimize waste.

Laser (laser cutting die) cuts corners precisely to reduce angled edges issues .

Adhesive Lamination :

Double-sided acrylic adhesive is laminated onto the foam via automated compound machines under controlled temperature/pressure.

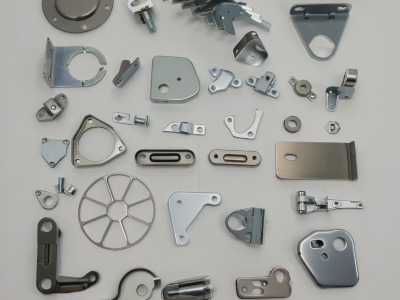

Nested Mod Die-Cutting :

Intelligent nested diecut designs maximize material usage (efficiency up to 93% ).

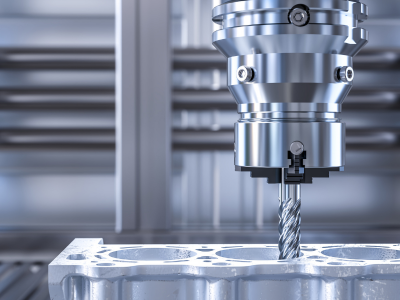

CNC (die-cutting machines) shape tape into custom geometries (e.g., PCB mounts, gaskets).

Waste Removal and Packaging :

Manual/automated waste removal ensures clean edges. Products are coiled or sheeted with protective release paper.

Post-Process and Quality Control

Post-Processing : Options include heat curing for enhanced adhesion, printing for part identification, and lamination with specialty films.

Quality Control :

ISO 9001-certified processes 4 with raw material inspections, in-process checks (thickness, adhesion strength), and final tests (peel strength ≥40N/cm, temperature resistance).

Performance validation via aging tests (UV/salt spray test exposure ) and batch consistency audits.

Cost-Saving Advantages

Material Optimization : Nesting algorithms reduce waste, lowering costs by 8–15%.

Alternative Designs : Hybrid structures (e.g., EVA +honeycomb paperboard) cut material use while maintaining protection.

Supply Chain Efficiency : Localized production and automated workflows minimize labor and lead times.

Delivery and Compliance

Lead Time : As fast as 5 days for standard orders, with expedited options.

Global Logistics : FOB/CFR/CIF terms supported; packaging tailored to prevent transit damage.

Compliance : Meets REACH, ROHS, and EU packaging standards.

Applications Across Industries

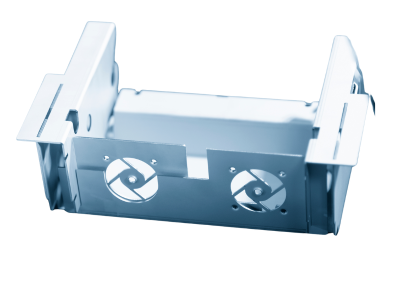

Electronics : PCB mounting, battery cushioning, and display sealing in smartphones, wearables.

Automotive : Interior trim adhesion, sensor mounting, and noise reduction in EVs.

Industrial Equipment : Dampening vibrations in motors/pumps and sealing HVAC systems .

Medical Devices : Shock-absorbing mounts for diagnostic equipment .

MFGsourcing leverages advanced die-cutting techniques and stringent QC to deliver cost-effective, reliable EVA foam tapes that accelerate product development and scale seamlessly into production. Contact us to prototype your solution within 7 days!

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsInquire

view details

view detailsCN ¥0.14

view details

view detailsCN ¥0.13

view details

view detailsInquire

view details

view detailsCN ¥0.38

view details

view detailsCN ¥0.55

view details

view detailsInquire

view details

view detailsInquire

本网页所展示的有关【Durable Double-Sided EVA Foam Pad for Electronics Manufacturing】的信息/图片/参数等由的会员【Dongguan MFG Sourcing Services】提供,由peakexporter.com会员【Dongguan MFG Sourcing Services 】自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。您在本网页可以浏览【Durable Double-Sided EVA Foam Pad for Electronics Manufacturing】有关的信息/图片/价格等及提供【Durable Double-Sided EVA Foam Pad for Electronics Manufacturing】的商家公司简介、联系方式等信息。

在您的合法权益受到侵害时,请您致电,我们将竭诚为您服务,感谢您对peakexporter.com的关注与支持!